CAPABILITIES

_____________________________________

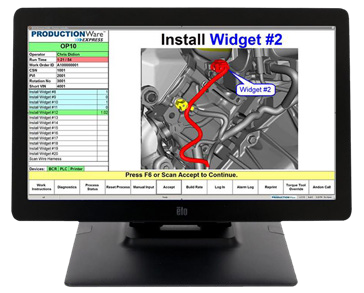

Error Proofing

Operator Certification

Component Validation

Pick-To-Light

Traceability

Batch Build / Kanban

Poka-Yoke

Audit

Lean Manufacturing

Standardized Work

Label Printing

Standardized Reports

Large Library of Commands

Scanning

Interfaces for Standard Devices

Adding Manufacturing Execution Systems to

your operations just got easier.

ProductionWare® Express is based on our flagship ProductionWare® product that has helped manufacturers ship quality product, every day, for decades. Designed to take advantage of the core functionality required in all of our ProductionWare® systems, this streamlined edition decreases the complexity and customization while still delivering the same exacting standards you expect.

Using an off-the-shelf approach with ProductionWare® Express, we have simplified the process of purchasing, implementing, administering and maintaining a reduced footprint assembly system. A ProductionWare® Express system includes almost everything you will need to implement up to a 5 station system. This includes the operating system, station hardware, and ProductionWare® Express Software.

Additional Modules can expand the possibilities of your ProductionWare® Express system. Should you need to grow your operations even further, we offer a migration path to our flagship product – ProductionWare®. In addition, you will have access to process configuration tools that will empower your team to administer the ProductionWare® Express system, which reduces your Total Life Cycle investment.

You need a partner that will deliver results in your plants with contemporary solutions propelling you forward, not holding you back. A partner with broad, global experience and a local touch, who can drive reliability and consistency in your operations, large or small, and far or near.