Operational Excellence in Manufacturing

What Lasting Partnerships in Manufacturing Really Mean

Manufacturing is not static. Product lines change. Regulations evolve. A long-term solution provider helps navigate that change, not just once, but over decades.

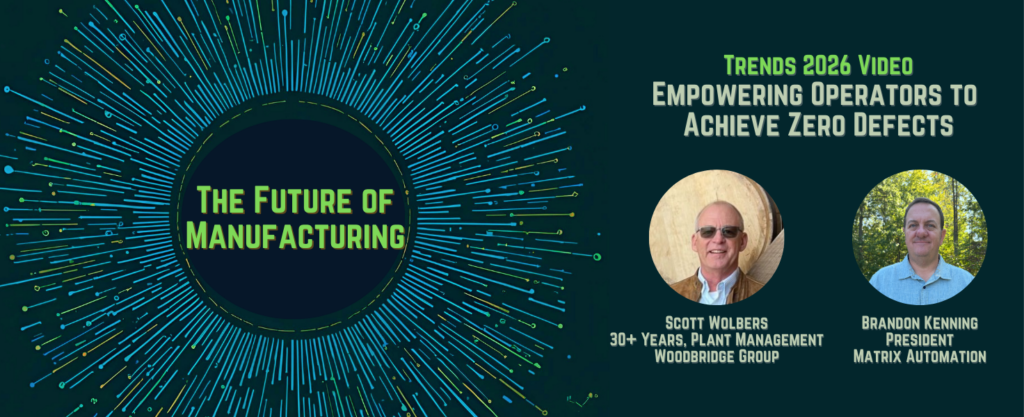

The Future of Manufacturing: Empowering Operators to Achieve Zero Defects

Error-Proofing Assembly Manufacturing: Ensuring Production Precision & Quality

Smaller buffers, shorter lead times, and leaner supply chains leave no room for error. Error-proofing can offer a systematic approach to help ensure manufacturing processes are as error-free as possible.

9 Tips to Reduce Operator Errors & Improve Quality

Yes, manufacturers can take errors down to zero or nearly zero. It’s not about perfect people; it’s about human-centered systems that provide a foundation for skills, rules, and knowledge.

Improving Quality in Assembly Manufacturing with Digital Work Instructions

Explore how digital work processes guide operators & increase quality in complex assembly manufacturing.

Top 7 Reasons Why MES Customization is Crucial for Manufacturing Teams

“Set and forget” is never a strategy for improvement. OT teams must be able to adapt their MES to support continuous improvement & increase opex.